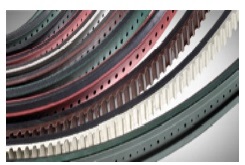

Power Transmission Belt

Composite construction with three different material traction layers coated with NBR rubber (partly with Hamid or leather), with different structures on both surface sides, in asymmetric and symmetric styles.

Asymmetrically built: A flat belts, partly TF and TCF series

Symmetrically built: Flat and tangential belts S, SP, CM, TC, partly TFseries

Conveyor Belt Belt Design

Habasit conveyor and processing belts are generally made of different layers, with tensile strength provided by synthetic fabric plies. These fabrics are connected with layers of thermoplastic materials in conveyor belts with multiple plies or fabric layers. Most heavy conveyor belts are produced with an interwoven or nonwoven “single ply” construction. The material, thickness and texture of the conveying side depend on the function of the belt.

Cover coatings are mainly made of thermoplastic materials like TPU, TPO, PVC, etc., and elastomer-like rubbers, PUR, etc. – or feature a fabric cover. The running side is usually a fabric, often impregnated with a thermoplastic material, or with special wear-resistant PUR that provides a low and constant coefficient of friction. There are also pulley-side fabrics that feature special low-noise running capabilities.

Reviews

There are no reviews yet.